For many sectors, different types of scissor lifts tables are relied upon to help with day to day operations. They are incredibly reliable, offering the speed and convenience that can’t be achieved by manual labour, thus streamlining operations and increasing efficiency.

With that said, it’s still important, as with any form of industrial equipment, that they are operated properly and safely. In this guide, we’ll discuss scissor lifts platforms in more detail, offering advice on how to ensure their safe operation, along with what the consequences of not doing so include.

What are Their Uses?

One of the most popular uses of a scissor lift platform is for the loading and unloading of goods. For example, they are commonly used in warehouses or distribution centres, allowing workers to safely, easily and efficiently access and move goods at different heights. They can also be used in commercial settings for a similar reason, with many supermarkets relying on them in their stock rooms and loading bays to help with the organisation of stock.

Types of Scissor Lift Platforms

We offer three distinct types of scissor lift platforms: loading bay lifts, Lightwell lifts and goods lifts. While you can find plenty more options offered under the Edmolift brand, we are the go-to choice for anyone looking for these lift types.

The Dangers of Operating a Scissor Lift Platform Improperly

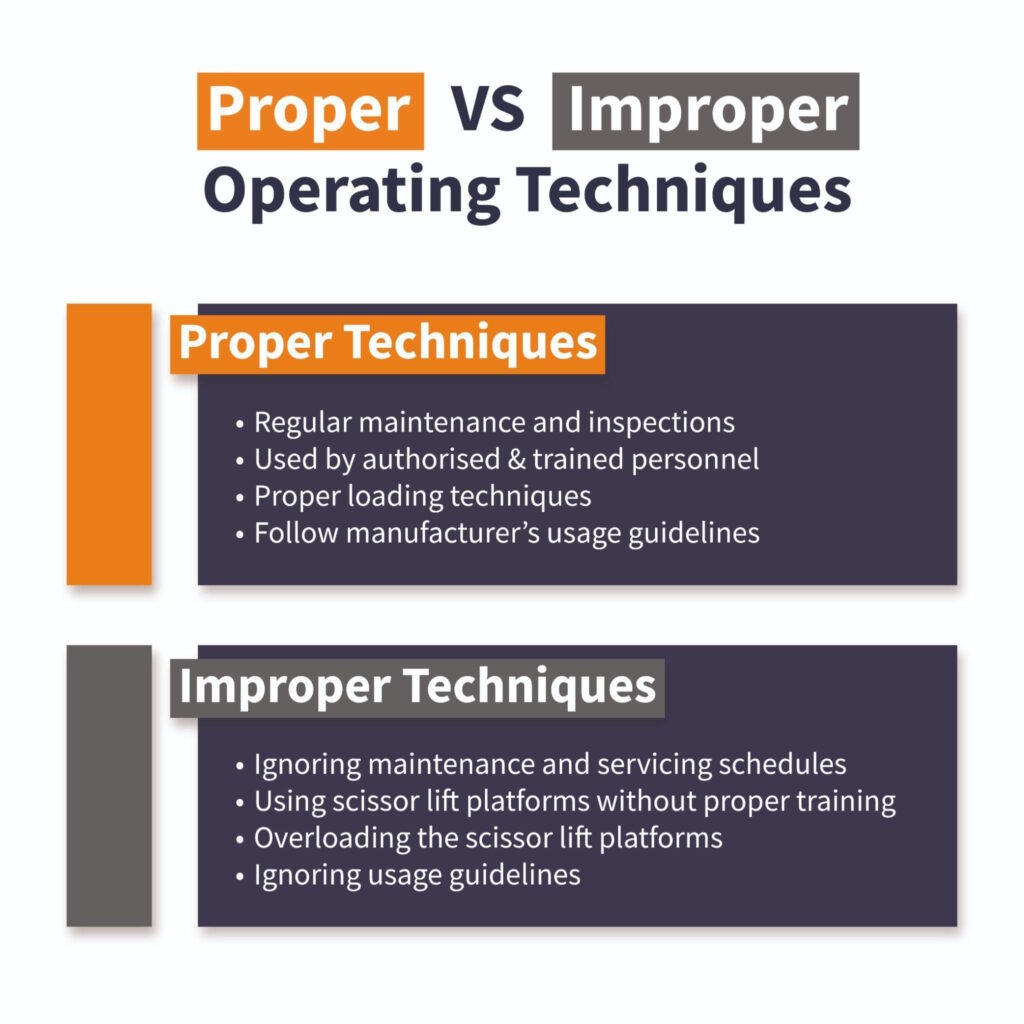

Now that you know a bit more about scissor lift tables, let’s look at how they operate. Whilst they are relatively user friendly, it’s still imperative that care is taken to ensure that scissor lift tables are being operated properly and according to the manufacturer’s guidelines at all times to avoid serious accidents to either cargo or personnel from occurring.

The most common dangers are caused by:

- Uneven distribution of weight due to cargo placement

- Overloading scissor lift platform

- Operating in hazardous work environments (e.g. strong winds, rainstorms)

- Lack of training and failure to follow correct operating and safety procedures and protocols

- Lack of regular preventative maintenance checks and interval servicing

How to Operate a Scissor Lift Platform Safely

Guidelines for Before Operation

Choose the Right Solution

Before installing a scissor lift platform, it’s important that you choose the right type for the job at hand. For example, if you need to transfer heavy goods and currently use an unsafe steel ramp, a goods lift is a highly adaptable scissor lift table solution while a lightwell lift can give you quick and easy access to a basement level.

You also want to ensure that you’re using a scissor lift platform that is the right size and capacity for your loading needs – do you require the platform simply to transport personnel and their tools, or will it be used to transport cargo?

Inspect Lift

Proper inspection should always be carried out before using your scissor lift platform. This includes looking out for:

- Cracks

- Damage

- Leaks (e.g. hydraulic oil or battery fluid)

- Worn out parts

- Additional defects

Should any issues be identified, then these should be rectified before the lift is operated.

Schedule Maintenance

It’s imperative that your scissor lift platform(s) undergoes regular maintenance and servicing, carried out by qualified and authorised servicing personnel. Not only does this help to increase its longevity, but ensures that any issues are identified and rectified promptly and your scissor lift platform is kept in optimum and safe working condition.

Guidelines for During Operation

Avoid Overloading

It’s important to know the safe working load of your scissor lift platform and ensure that this is not exceeded during operation. If you overload your scissor lift platform, then it could cause damage or malfunction, and may even pose a safety risk to surrounding individuals.

Load Placement

If transporting goods in your scissor lift platform, then it’s best to place heavy loads in the centre of the lifting table. This ensures that the weight is distributed more evenly and reduces the chances of cargo falling or tip-overs from occurring if placed to one side of the lifting table.

Follow Usage Guidelines

After investing in a scissor lift platform, it will have likely come with manufacturer’s guidelines on safe and proper usage techniques. Regardless of whether you’re lifting cargo or personnel, ensure that you follow the listed guidelines to ensure proper use and safety. For example, workers should not overcrowd the lift platform and always stand upright with both feet on the platform whilst holding onto the handrail as they’re being elevated.

Loading Bay Scissor Lifts

Here at Edmolift, we’re scissor lift platform specialists – whatever your loading and lifting needs are, we’ve got you covered.

From loading bay lifts to goods lifts, we’re able to offer you a range of standard or bespoke solutions, allowing you to find the ideal lift to suit your unique requirements. Site survey visits are attended free of charge by our highly experienced engineering team to ascertain which product will suit your requirements and provide a cost effective solution.

To learn more about what we can offer you, then don’t hesitate to get in touch with us today.