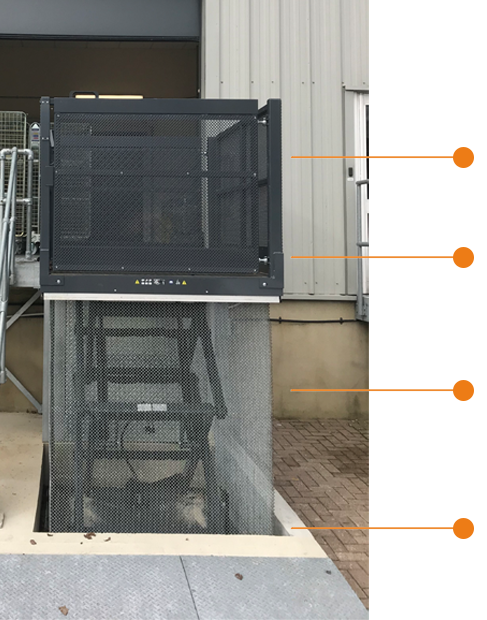

Loading Bay Lifts

Front of Dock & Split Level

Loading bay lifts / dock lifts for front of dock applications are used to transfer loads between rear of vehicle and dock or from dock to ground level. Moving waste bins, roll cages and pallets are very common reason for using this type of safe, efficient and reliable lift.

Also, we offer a large variety of options including interlocked gates and barrier arms, handrails, hinged bridge plates with manual and powered operation, buffers and ramps. These lifts can be floor mounted but more often they are pit installed for flush floor level loading.

Unico & Multi-Dock Pit Free Loading Bay Lifts

We have both Unico and Multi-Dock loading bay lifts. These can be used for free standing open yard applications or directly against a dock. They do not require a pit! Providing a very adaptable solution that’s easy to move from location to location and has a lifting capacity up to 3000Kg.

Manual and powered bridge plates are available, interlocked gates and goal post barriers. Multi-Dock models have twin safety zones for the travelling operator. The raised height is 1600mm.

In-Dock Loading Bay Lifts

We have loading bay lifts set within the dock or within the building have the advantage of improved security, temperature regulation, hygiene and weather protection. Often the vehicle can reverse directly against the lift and building with a seal for added protection.

The lift is designed to suit your architectural requirements. We can work with your builder to ensure the pit size and aperture are correct and understood. Lifts can be fitted with manual and powered bridge plates.

Standard & Bespoke Solutions

We offer a range of bespoke platform sizes, configurations and barrier styles to suit your exact requirements. Choose from interlocked gates, goal posts, open or clad barriers, lift up barriers, manual or powered hydraulic bridge plates. Our lifts can also be integrated with dock doors and seals.

Our platform surfaces are available in a choice of slip resistant finishes such as tread plate, grit paint, fibregrid and treadtex, so you can find the perfect material for your needs. Lifts can be finished in stainless steel and galvanised materials, where all RAL powder coat C4 paint colours are also available.

Choose a lifting capacity to suit you, where our installations can hold between 1000 and 25,000 kg. All of our lifts have two or four chromed, honed and air tested hydraulic cylinders. These come complete with rupture valves, wiper seals, clapet valves and armoured hoses. We also utilise high tensile boxes and I profile scissor mechanisms with torsion bars to provide optimum strength and stability to your lift system.

We can install remotely mounted or integral microprocessor controlled power packs, 3ph or 1ph with 24vDC control systems, as well as deadman “press to run” controls positioned in locations of your choice. Our range also includes IP54/IP66 switch gear, overload protection pressure valves, adjustable flow valves and oil level indicators.

Can’t find what you’re looking for?

Please do not hesitate to call one of our experts at: 01440 730640

Or visit some of the other pages we have available: Goods Lifts | Lightwell lifts

Finally, if you cannot find what you’re looking for on this website be sure to check our our sister site: www.edmolift.co.uk

For all things scissor lift tables and manual handling.